- New Inventory

Inventory

Services

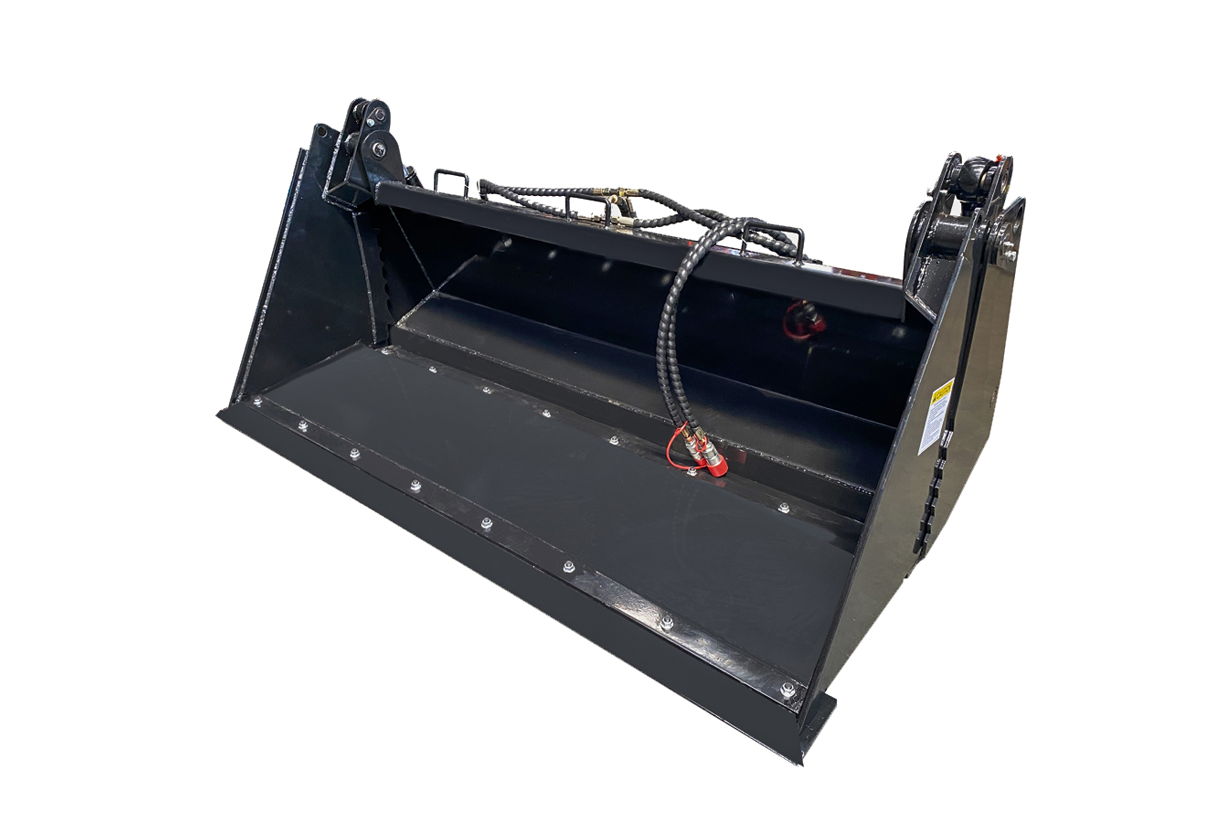

Bobcat Disc Mulcher – 48″, 88cc

The disc mulcher functions like a flywheel, storing kinetic energy to slice through tough material and shred it into mulch. The stored energy minimizes the performance demands on your loader and helps reduce operating temperatures. Cut trees up to 14 inches in diameter. Turns trees up to 6 inches in diameter into beds of mulch. Four-point hardened-steel knives on the outer edge and planer knives throughout the underside pulverize trees and other dense material. Flywheel design stores kinetic energy to slice and shred through tough material.

Bobcat Disc Mulcher – 48″, 88cc

Let's Get Started

"*" indicates required fields

Key Specifications

Operating Weight 1625 lb

Length 64.2 in

Width 63.1 in

Height 36.9 in

Cutting Width 48 in

Hydraulic Flow Range 23-29 gal/min, 92-116 l/min

Outer Tip Speed - Min Flow 10,620 ft/min

Outer Tip Speed - Max Flow 13,440 ft/min

Cutting Capacity Brush Material up to 14" (356mm) Diameter Maximum for All Models

Key Features

Powerful Cutting and Mulching Action Machined from high-strength one-inch-thick steel, the disc meets strict specifications for well-balanced rotation and high-speed cutting performance. The disc mulcher can cut trees up to 14 inches in diameter and turn trees up to 6 inches in diameter into beds of mulch. The disc mulcher can cut at ground level and supports an impressive vertical reach.

Hardened Steel Teeth Case-hardened steel teeth are fixed to the inside of the deck shell, and they mulch material as the rotating disc carries trees and brush through the attachment. These four-point teeth can be easily sharpened and rotated to maximize efficiency. The planter knives in the center of the disc eliminate dead zones for effective, easy land clearing, regardless of the attachment’s position.

High-Torque Hydraulic Gear Motor The hydraulic gear motors efficiently handle the bulk of tough land-clearing applications with ease. These gear motors generate high torque and collectively support three hydraulic flow ranges: standard, high and super flow. The gear motors also feature a relief valve to protect against overpressurization.

Push Bar A push bar on the front of the disc mulcher helps operators direct the fall of trees and heavy brush for productive processing.

Simple Maintenance The spindle bearings are lubricated with gear oil that should be replaced once every year or every 500 hours, whichever comes first. Operators have easy access to the disc teeth, the motor hardware and the spindle hardware, which should be inspected daily, or every 10 hours, to ensure optimum performance.

Protective Motor Cover A steel covering shields the hydraulic motor, protecting it from contact and damage.

Two Intake Configurations The disc mulcher features two intake configurations to optimize the intake flow of varying tree sizes and material densities.

(256) 895-3311

(256) 895-3311 7238 Governors W.

7238 Governors W. Get In Touch

Get In Touch